Products

Bulk Molding Compound (BMC) Manufacturer Ethiopia

Huayuan Advanced Materials Co., Ltd. (HAMC) is one of the earliest manufacturers of BMC and its equipment in China. It has provided complete equipment manufacturing and technical services as well as integrated services for international trade for over 26 years. HAMC has gained long term & global partnership with Siemens, GE, Schneider, Eaton, Cummins. HAMC's BMC is well-known around the world, especially in Ethiopia. HAMC's BMC has good after-sales service in Ethiopia, and it is supplied to Ethiopia distributors for a long time.

What's BMC?

BMC has good physical properties, electrical properties and mechanical properties, so it is widely used. For example, it can produce mechanical parts such as gearbox components, intake pipes, valve bonnets, bumpers, etc. Durable aviation, construction, furniture, etc. are also widely used; in its traditional electrical field, its use is becoming more and more widespread.

Solutions and Services Provided by HAMC

HAMC provides cost-effective, high-performance BMC. If you want to obtain products with the above characteristics or reduce costs, you can usually use BMC instead of metals, thermoplastics, phenolic or epoxy. BMC produced by HAMC is used to manufacture electrical insulation parts, motor brackets, automobile headlight housings, and various structures and protection components for different industries. HAMC has more than 26 years of experience in designing ideal and cost-effective BMC materials for customers in various industries and applications. Please contact us for detailed information, we believe you will find your solution.

The Reasons Why Our BMC Are Popular in Ethiopia

Quality assurance: The quality of our products conforms to the various testing and certification of us. With over 26 years efforts put into this industry, HAMC now has become the industry leader in China. The BMC that HAMC has formulated and compounded are now widely used in China as well as all over the world in varieties of industry applications.

There are distributors in Ethiopia: our customers are all over the world. We plan to produce overseas to provide faster and better service.

HAMC has established an advanced factory of more than 70,000 square meters in China. The area of the R & D center also exceeds 4,000 square meters.

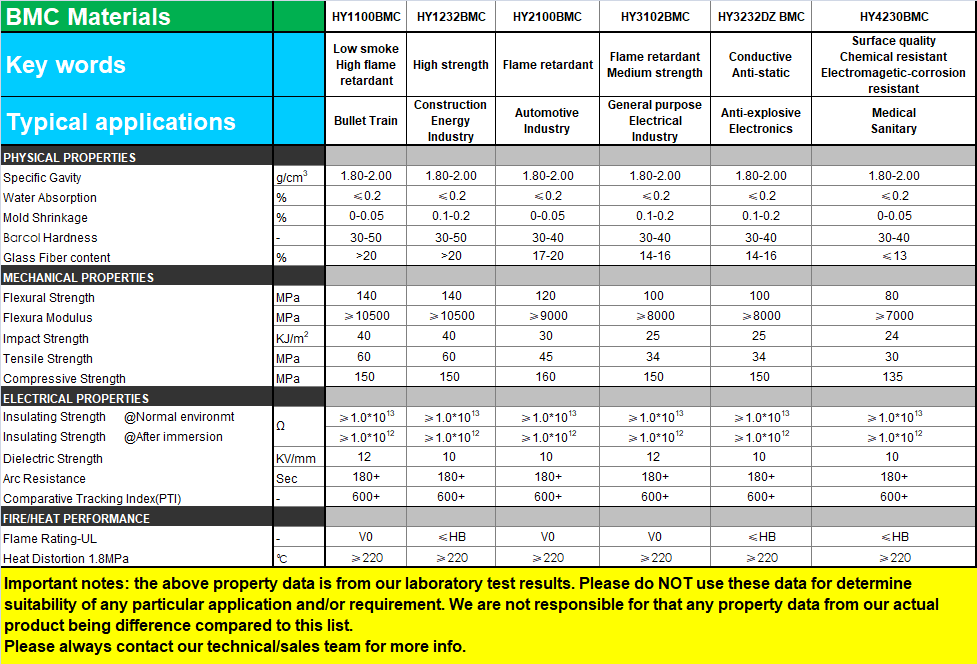

Various specifications are provided:

If you are looking for a competitive price and high quality BMC material manufacturing partner recently, please contact HAMC for a quotation.

BMC Molded Motor Covers

Motor cover is a typical application of bulk molding compound (BMC) material. It replaced die cast aluminum/zinc parts by offering various advantages.

BMC Molded Motor Covers

Motor cover is a typical application of bulk molding compound (BMC) material. It replaced die cast aluminum/zinc parts by offering various advantages.

BMC Molded Insulation Parts

Using bulk molding compound (BMC) materials to produce Circuit Breaker Base & Cover and insulation parts is one of the most popular designs for circuit breaker providers.

BMC Molded Insulation Parts

Using bulk molding compound (BMC) materials to produce Circuit Breaker Base & Cover and insulation parts is one of the most popular designs for circuit breaker providers.

BMC Busbar Clamps

With RTI of 130°, very good electrical insulation property, and high mechanical strength, bulk molding compound (BMC) and sheet molding compound (SMC) are the perfect choices for making bus bar clamps.

BMC Busbar Clamps

With RTI of 130°, very good electrical insulation property, and high mechanical strength, bulk molding compound (BMC) and sheet molding compound (SMC) are the perfect choices for making bus bar clamps.

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Refill