Leading Bulk Molding Compound Manufacturer in China

Since 2000

Reliable Bulk Molding Compound Manufacturer

What Is Bulk Molding Compound (BMC)

Bulk Molding Compound (BMC) is a fiber-reinforced composite material that is widely used for producing complex, high-performance parts. It consists of short glass fibers (usually ranging from 3mm to 9mm) embedded in an unsaturated polyester or vinyl ester resin. Additional fillers and additives are included to enhance the material’s properties, such as shrinking agents, pigments, mold release agents, and catalysts.

Compared to SMC (Sheet Molding Compound), BMC materials have better fluidity, making them ideal for creating more intricate shapes with superior finishes. This versatility in molding results in BMC being used for a wide variety of products across multiple industries.

Key Features of Bulk Molding Compound (BMC)

BMC materials have several outstanding properties that make them ideal for a broad spectrum of applications:

- Lightweight: BMC components are up to 40% lighter than aluminum, reducing the overall weight of products without compromising strength, making them ideal for applications in the automotive and aerospace industries.

- High Strength: Bulk Molding Compound offers exceptional tensile strength. The compression molding process enables the creation of parts with integrated stiffeners and supports, providing higher load-bearing capacity than metals.

- Corrosion-Resistant: BMC materials are resistant to solvents and corrosion, making them suitable for use in harsh outdoor and industrial environments.

- Cost-Effective: When looking for more affordable alternatives to metals or thermoplastics, BMC offers a more economical solution while still meeting performance requirements. The manufacturing complexity of BMC is significantly lower than that of continuous fiber composites.

- Easy to Manufacture: The lubrication and mold-release properties of BMC materials make the production process smoother, more efficient, and cost-effective.

- Durability: BMC has excellent electrical insulation properties, fire resistance, heat resistance, weather resistance, low shrinkage, and stable dimensional control. These characteristics make BMC an ideal choice for manufacturing small, complex, and precise components.

| BMC Materials | HY1100 BMC | HY1232 SMC | HY2100 BMC | HY3102 BMC | HY3232DZ BMC | HY4230 BMC | |

| Key Words |

Low smoke High flame retardant |

High strength | Flame retardant |

Flame retardant Medium strength |

Conductive Anti-static |

Surface quality Chemical resistant Electromagatic-corrosion resistant |

|

| Typical Applications | Bulltet Train |

Construction Energy Industry |

Automotive Industry |

General purpose Electrical Industry |

Anti-explosive Electronics |

Medical Sanitary |

|

| Physical Properties | |||||||

| Specific Gavity | g/cm³ | 1.80-2.00 | 1.80-2.00 | 1.80-2.00 | 1.80-2.00 | 1.80-2.00 | 1.80-2.00 |

| Water Absorption | % | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

| Mold Shrinkage | % | 0-0.05 | 0.1-0.2 | 0-0.05 | 0.1-0.2 | 0.1-0.2 | 0-0.05 |

| Barcol Hardness | - | 30-50 | 30-50 | 30-40 | 30-40 | 30-40 | 30-40 |

| Glass Fiber Contect | % | ≥20 | ≥20 | 17-20 | 14-16 | 14-16 | ≤13 |

| Mechanical Properties | |||||||

| Flexural Strength | Mpa | 140 | 140 | 120 | 100 | 100 | 80 |

| Flexura Modulus | Mpa | ≥10500 | ≥10500 | ≥9000 | ≥8000 | ≥8000 | ≥7000 |

| Impact Strength | KJ/m² | 40 | 40 | 30 | 25 | 25 | 24 |

| Tensile Strength | Mpa | 60 | 60 | 45 | 34 | 34 | 30 |

| Compreesive Strength | Mpa | 150 | 150 | 160 | 150 | 150 | 135 |

| Electrical Properties | |||||||

| Insulating Strength @Normal environment | Ω | ≥1.0*1013 | ≥1.0*1013 | ≥1.0*1013 | ≥1.0*1013 | ≥1.0*1013 | ≥1.0*1013 |

| Insulating Strength @After immersion | ≥1.0*1012 | ≥1.0*1012 | ≥1.0*1012 | ≥1.0*1012 | ≥1.0*1012 | ≥1.0*1012 | |

| Dielectric Strength | KV/mm | 12 | 10 | 10 | 12 | 10 | 10 |

| Arc Resistance | Sec | 180+ | 180+ | 180+ | 180+ | 180+ | 180+ |

| Comparative Tracking Index(PTI) | - | 600+ | 600+ | 600+ | 600+ | 600+ | 600+ |

| Fire/Heat Performance | |||||||

| Flame Rating-UL | - | V0 | ≤HB | V0 | V0 | ≤HB | ≤HB |

| Heat Distortion 1.8Mpa | ℃ | ≥220 | ≥220 | ≥220 | ≥220 | ≥220 | ≥220 |

|

Important Notes: the above property data is from our laboratory test results. Please do NOT use these data for determine suitability of any particular application and/pr requirement. We are not responsible for that any property data from our actual product being difference compared to this list. Please always contact our technical/sales team for maore info. |

|||||||

Application of Bulk Molding Compound (BMC)

BMC materials are highly versatile and can replace metals, thermoplastics, and other composite materials in a wide range of applications. Here are some common uses of Bulk Molding Compound:

- Automotive Parts: Gearboxes, intake pipes, bumpers, and valve covers.

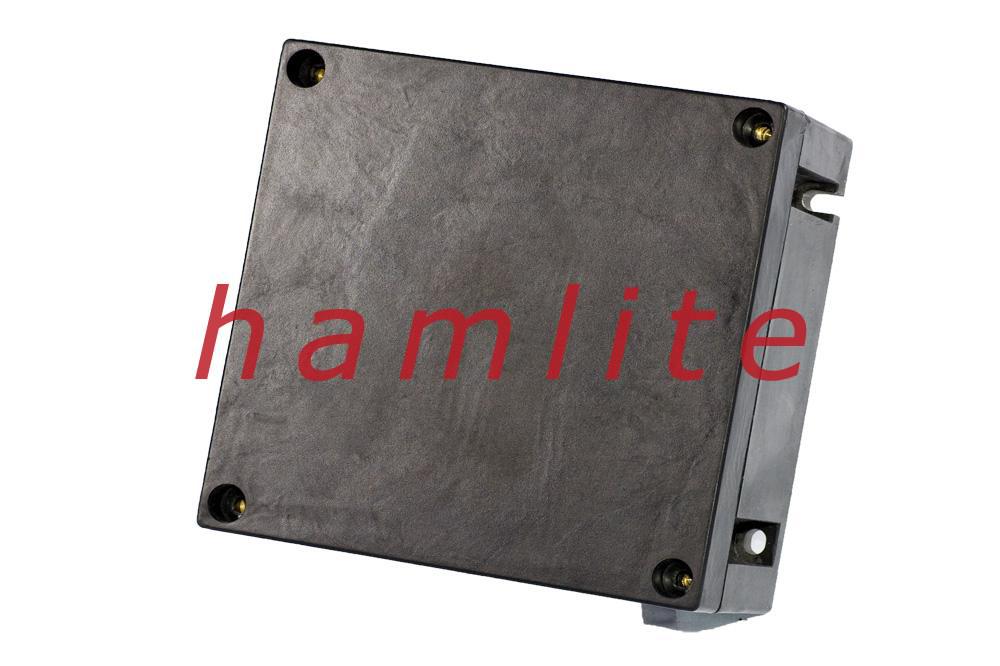

- Electrical Components: Insulators, motor brackets, and switch boxes.

- Telecommunications: Cabinets, housings, and other outdoor telecom equipment.

- Industrial Applications: Structural supports, protective parts, and durable components for construction and manufacturing.

- Consumer Goods: Furniture parts and various lightweight structural components.

Why Choose Us

HAMC's Bulk Molding Compound (BMC) Solution

HAMC specializes in providing high-quality BMC materials that meet the specific requirements of various industries. Whether you are replacing metals, thermoplastics, or other resins, BMC offers an ideal solution for a wide range of applications. With over 26 years of expertise in Bulk Molding Compound production, we offer tailored solutions to meet your unique needs.

We work closely with our clients to design BMC materials that offer superior mechanical, electrical, and physical properties. From compound formulation to mold and process analysis, HAMC’s technical team is equipped to help you create cost-effective, high-performance parts for your industry. (Contact Us)

The BMC Development Process

The development of BMC materials involves careful planning and execution to ensure that each part meets customer specifications and industry standards. The development process at HAMC includes:

-

Detailed Analysis: We start by working with you to identify the specific requirements for your project, analyzing specifications, usage conditions, and performance goals.

-

Customized Formula Development: Based on the analysis, our technical team develops customized BMC formulations tailored to meet the specific performance characteristics you require, such as flame retardancy, color, or enhanced strength.

-

Prototyping: We use advanced prototyping tools to test the custom BMC materials and ensure they meet your design requirements before full-scale production begins.

-

Optimization: After prototyping, we refine the production process, ensuring that the final product is cost-effective, high-performing, and manufactured efficiently.

-

Full-Scale Manufacturing: Once the design and prototyping phases are completed, HAMC moves to full-scale manufacturing using our state-of-the-art facilities and quality control processes to ensure consistent results.

High-quality Bulk Molding Compound (BMC) Materials from HAMC

At HAMC, we are committed to providing the highest quality BMC materials to our customers. We follow a rigorous quality control process at every stage of production, ensuring that every batch of bulk molding compound meets the highest standards for performance and reliability. Our R&D and manufacturing facilities are equipped with advanced technologies, and we work closely with global partners such as AOC Aliancys Resins, BYK, and Owens Corning to ensure the continuous improvement of our products.

Why Choose Us

-

Industry Leadership: HAMC is one of the leading BMC materials manufacturers in China and a key player in the development of composite material standards.

-

Expertise: With over 26 years of experience in the Bulk Molding Compound industry, our team has the technical knowledge and expertise to solve the most complex challenges.

-

State-of-the-Art Facilities: HAMC’s advanced manufacturing facility spans over 70,000 square meters, and our R&D center exceeds 4,000 square meters, ensuring we can deliver high-quality products at scale.

-

Global Experience: We have extensive experience working with industry leaders such as Huawei, Siemens, ZTE, 3M, and Tyco, both in China and internationally.

-

Tailored Solutions: Our team of engineers collaborates closely with clients to create customized BMC solutions that meet the unique requirements of each project.

Contact HAMC for Your Bulk Molding Compound Needs

Looking for BMC materials that deliver superior performance, cost-efficiency, and reliability? Contact HAMC today. With over 26 years of experience and a commitment to excellence, we are ready to help you find the perfect Bulk Molding Compound solution for your industry.

Bulk Molding Compound - All You Need to Know

Related Articles

Top 10 Composite Manufacturers in the World 2025

China Top 5 BMC Mold Manufacturers 2025

Top 10 Compression Molding Companies List 2025

What Is Bulk Molding Compound (BMC): 2025 Definitive Guide

SMC VS BMC: What's the Difference

What Are the Common Composite Materials? The Most Complete List