Automotive industry uses the most volume of Sheet Molding Compound (SMC) & Bulk Molding Compound (BMC) material in both USA and Europe markets. It is the biggest market for Sheet Molding Compound (SMC) & Bulk Molding Compound (BMC) material.

There are three main sectors of this industry, heavy trucks, passenger cars, and tractors. Sheet Molding

Compound (SMC) and Bulk Molding Compound (BMC) material is used for both interior and exterior automotive parts.

There are many reasons to why Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) material is so widely used in this industry. Mainly because Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) material offers weight saving, high mechanical performance, excellent dimension stability, low thermal expansion coefficient, free design flexibility, class A finish and acceptability to extreme quality painting finish.

Below are some typical parts made up of Sheet Molding Compound (SMC) & Bulk Molding Compound (BMC) material:

* Headlamp housings (BMC)

* ETC valve housings (BMC)

* Engine housings (BMC & SMC)

* Various interior parts (Bulk Molding Compound (BMC &SMC)

* Trunk covers (SMC)

* Bumpers (SMC)

* Front Faces (SMC)

* Deflectors (SMC)

* Fenders (SMC)

* Gasoline tank bottom shells (SMC)

* Truck step panels (SMC)

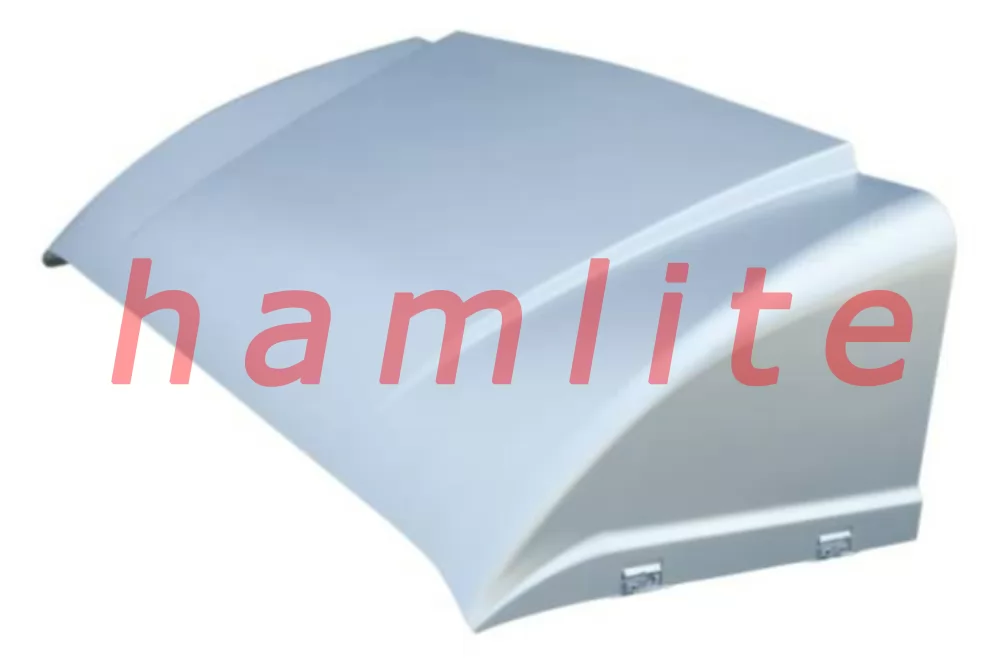

* Tractor roofs (SMC)

* Tractor exterior shells (SMC)

* Battery enclosures for BEV & Hybrid-Vehicle (SMC)

Huayuan gains various of experiences in automotive industry over the past twenty years, both in Sheet Molding Compound (SMC) & Bulk Molding Compound (BMC) material side and auto-parts production side. Please feel free to contact us and discuss your projects.